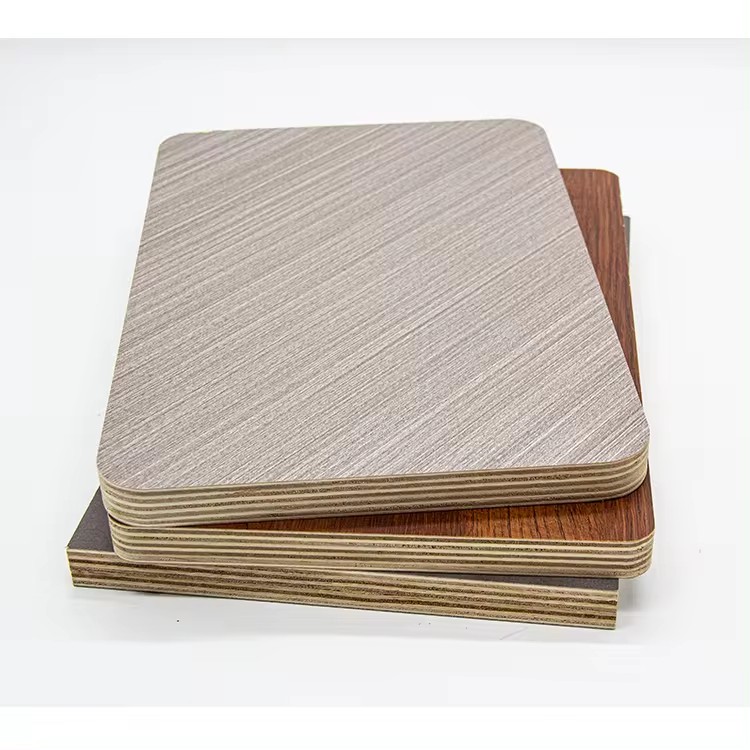

what is laminated furniture board?

Laminated furniture board refers to a type of composite material commonly used in the production of furniture. It consists of multiple layers that are bonded together to create a single board. Here are some key features and benefits of laminated furniture board: 1. **Durable**: It can withstand wear and tear, making it suitable for various types of furniture. 2. **Cost-effective**: Usually relatively inexpensive compared to other high-quality materials. 3. **Uniform appearance**: Provides a consistent look throughout the board. 4. **Easy to work with**: Can be cut, shaped, and finished easily. 5. **Moisture resistance**: Resistant to moisture, which helps prevent warping or swelling. 6. **Improved strength**: The multiple layers add to its overall strength. 7. **Versatile design options**: It can be decorated or finished in a variety of ways. 8. **Easy maintenance**: Can be cleaned with mild cleaners. Some common uses of laminated furniture board include: 1. Cabinetry. 2. Shelving. 3. Tables. 4. Desks. However, some potential drawbacks include: 1. Limited durability compared to solid wood. 2. May not have the same natural look or feel as solid wood.

Laminate production process

The following is some information about the production process of laminated furniture board:

1. ** Raw material preparation ** : Select the appropriate substrate, such as particleboard, MDF, etc.

2. ** Surface treatment ** : Sanding, grinding and other treatment of the substrate to ensure the surface is smooth.

3. ** Glue ** : Use the appropriate adhesive evenly coated on the substrate.

4. ** Veneer preparation ** : Prepare the veneer to be laminated, usually thin wood chips or paper material.

5. ** Laminating ** : Place the veneer layer by layer on the substrate coated with adhesive, and bond it by pressure and temperature.

6. ** Press ** : Use a press to press the laminate to ensure tight bonding between the layers.

7. ** Trimming and cutting ** : Trimming and cutting the pressed plate to achieve the required size and shape.

8. ** Quality inspection ** : Check the appearance of the product, flatness, bonding strength and other quality indicators.

The exact details of the production process may vary depending on the manufacturer and product requirements. Here are some factors that can affect the production process:

1. ** Adhesive selection ** : affects bonding strength and environmental performance.

2. ** Veneer quality ** : such as thickness, flatness and material.

3. ** Pressing conditions ** : including pressure, temperature and time.

4. ** Quality control ** : To ensure that products comply with relevant standards and requirements.

light oak furniture board,

light grey furniture board,

light oak effect furniture board,

furniture board made to measure,

furniture melamine board