When it comes to selecting materials for your next construction or DIY project, you may find yourself torn between two common options: particle board and marine plywood. While both serve as popular choices in the world of building materials, understanding their differences can help you make an informed decision tailored to your specific needs.

Particle board, sometimes called chipboard, is a type of engineered wood that consists of tiny wood particles held together by resins. This material often features a smoother surface on one side, with the other side being somewhat rougher. It is typically less expensive than other types of wood panels and has a range of uses, including furniture construction, shelving, and cabinetry, among others. One particular variant of particle board, known as 38mm particle board, offers additional thickness, making it suitable for certain applications where strength is a factor. However, it’s worth noting that particle board is generally less durable than solid wood and can be susceptible to moisture damage if not properly sealed.

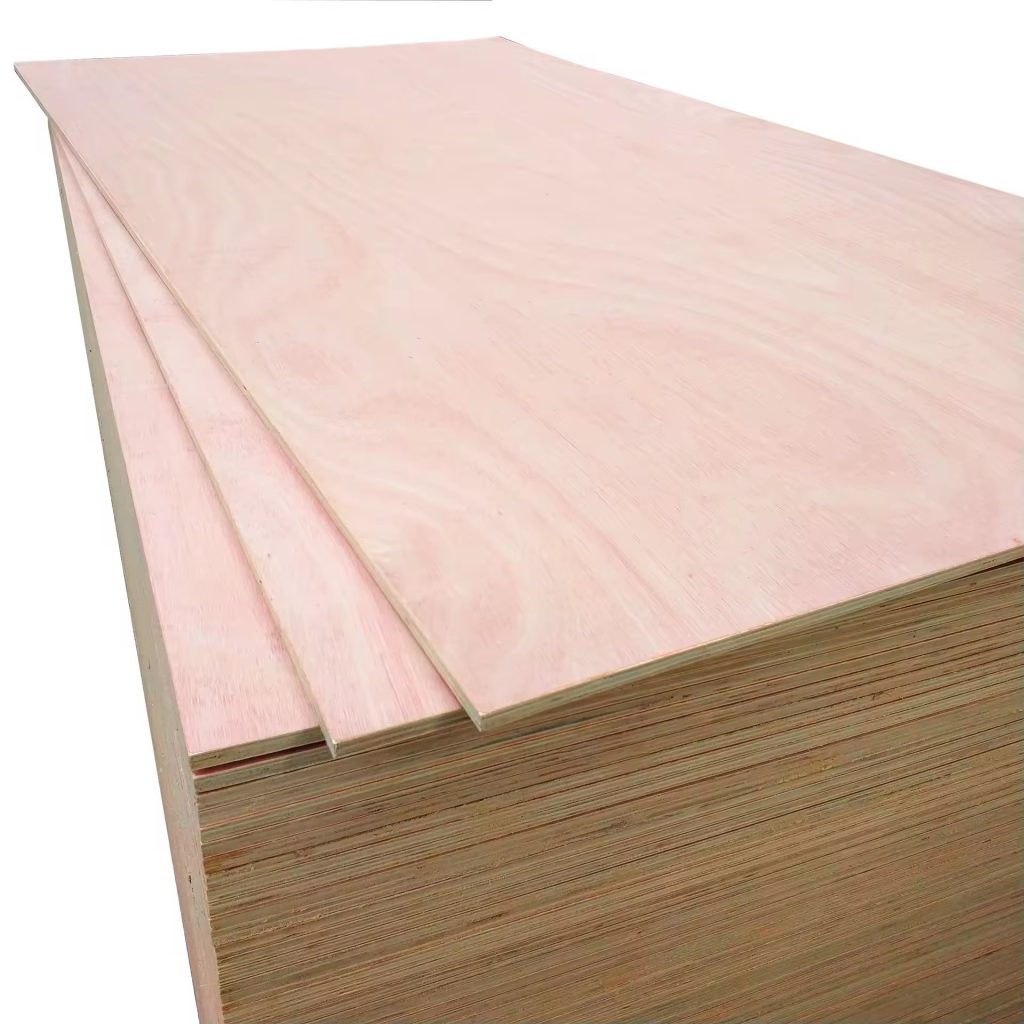

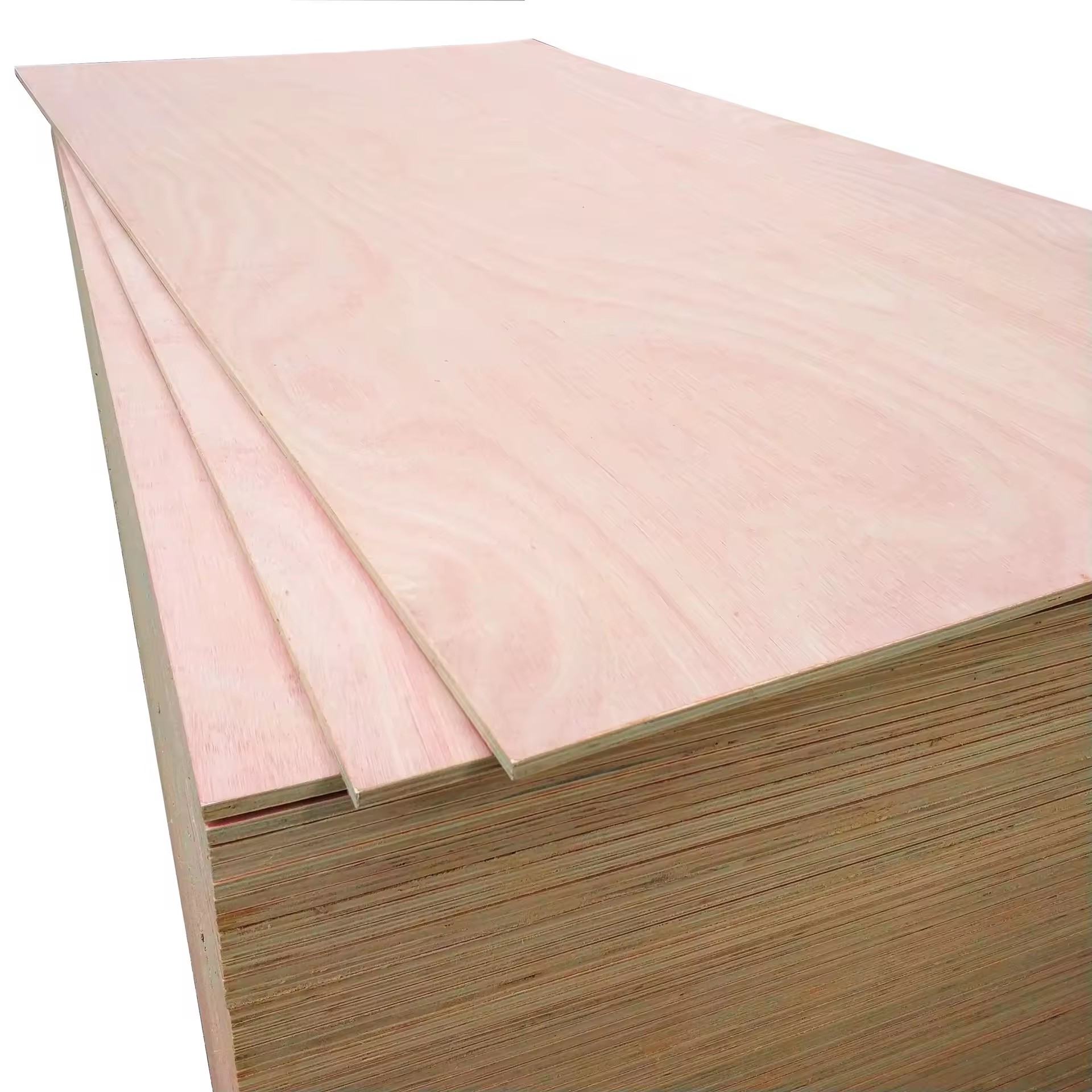

In contrast, marine plywood is a form of plywood specifically designed to withstand exposure to water and moisture. It is made from rot-resistant hardwood veneers and is bonded together with waterproof adhesives. The layers are arranged in a cross-grain pattern that increases the panel’s strength and stability. Marine plywood is commonly used in boatbuilding, docks, and any other structure expected to come into contact with water or humidity. Its resistance to moisture makes it an ideal choice for outdoor projects or those in areas prone to dampness.

Comparing the two, particle board and marine plywood have distinct advantages and disadvantages. Particle board’s main advantage lies in its affordability; it’s a cost-effective solution when compared to more robust materials like marine plywood. Additionally, it’s lightweight and easy to work with, making it convenient for beginners or those looking to handle projects themselves. On the flip side, particle board does suffer from a lack of durability and can degrade quickly in wet conditions unless treated correctly.

On the contrary, marine plywood’s greatest attribute is its superior resistance to water and humidity, making it the go-to choice for marine environments and high moisture areas. Despite this, marine plywood is usually more expensive due to its specialized nature and manufacturing process. It’s also heavier compared to particle board, which might add complexity to the installation process and could require stronger foundational structures.

Ultimately, choosing between 38mm particle board and marine plywood depends on several factors, including the intended use, environmental conditions, budget, and personal preference. If you need a budget-friendly option that is easy to work with, particle board might be the way to go. Conversely, if your project is situated in a wet environment or requires long-term durability against moisture, marine plywood would be the sturdier and more reliable choice.

To summarize, while both particle board and marine plywood have their merits, they cater to different scenarios based on their unique properties. By evaluating these distinctions carefully, you can determine which material aligns better with your project requirements, ensuring that your construction turns out both successful and sustainable in the long run.