Is HPL better than MDF board?

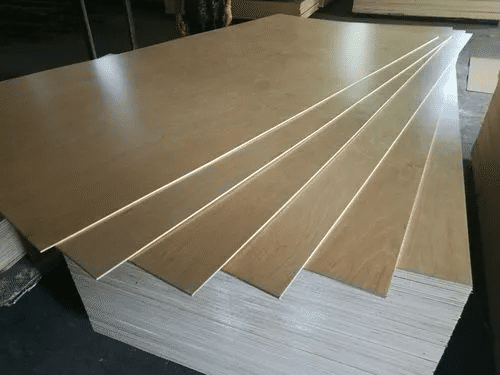

HPL and MDF boards are both widely used in construction but have key differences. HPL is a durable melamine board resistant to moisture and stains, making it ideal for spill-prone areas like kitchens. However, it can be more expensive than MDF, which is made from resin-bound wood fibers and offers greater affordability. MDF boards are also denser and may warp less than HPL. Consider the project’s needs when choosing between them as HPL may offer better durability, while MDF is more budget-friendly and easier to work with.