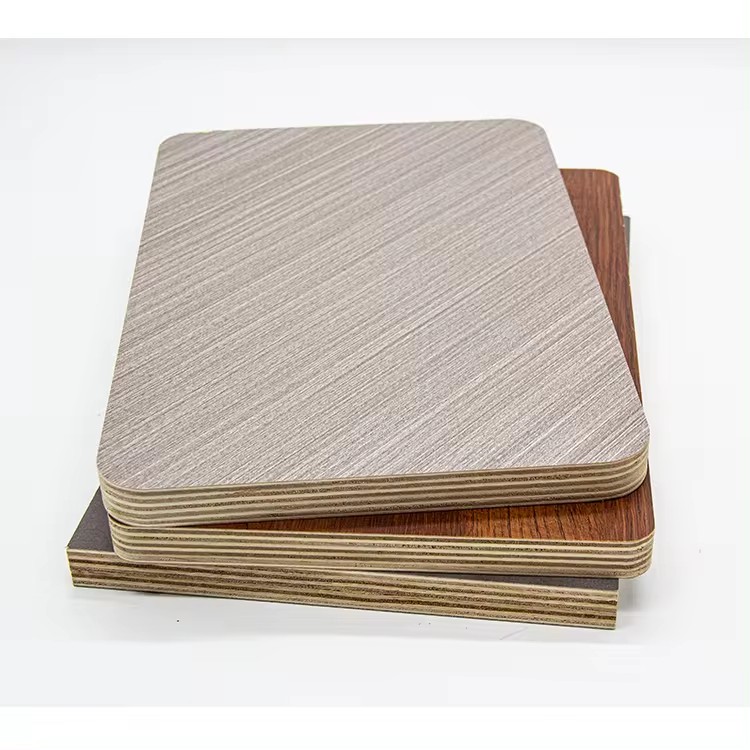

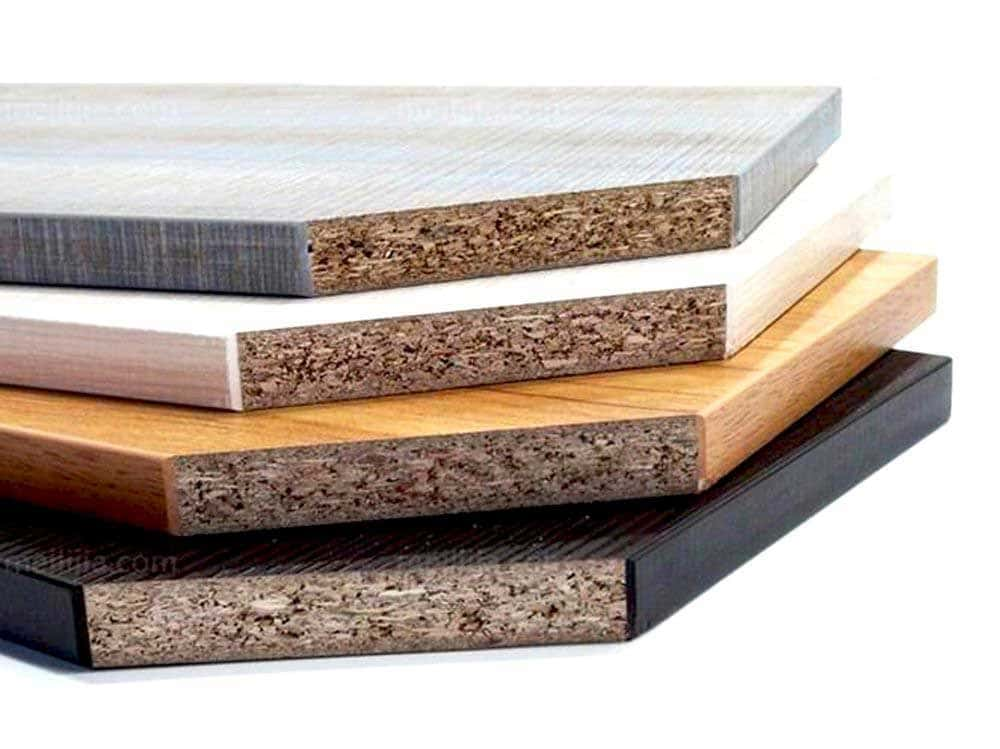

Types of Veneer Plywood?

veneer plywood manufacturers,veneer plywood 4×8,4x8ft plywood veneer Understanding the different types of veneer plywood is crucial for selecting the right material for your project. Whether you need the aesthetic appeal of hardwood veneer plywood, the flexibility of bendy plywood, or the durability of marine grade veneer plywood, there is a product to meet your needs. […]