MDF Board Epoxy

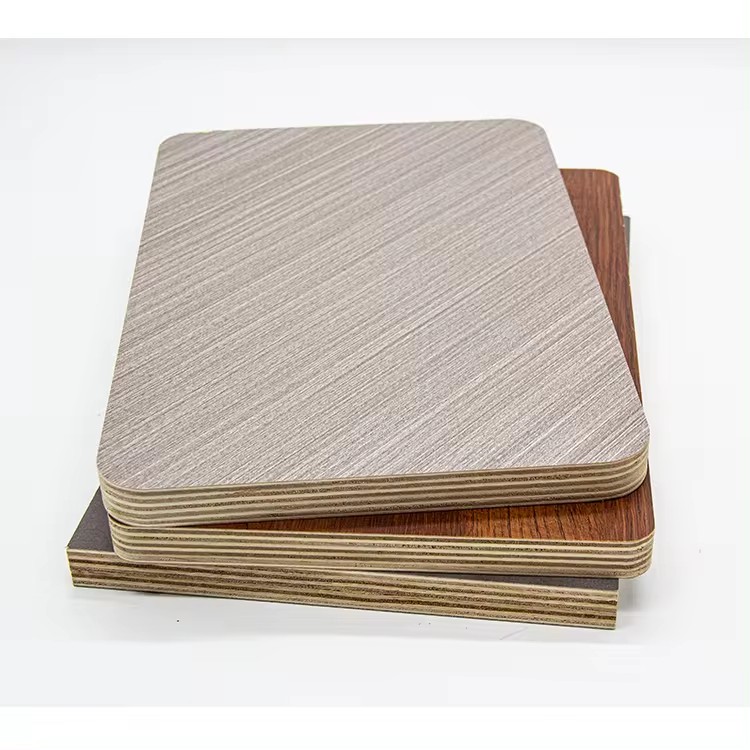

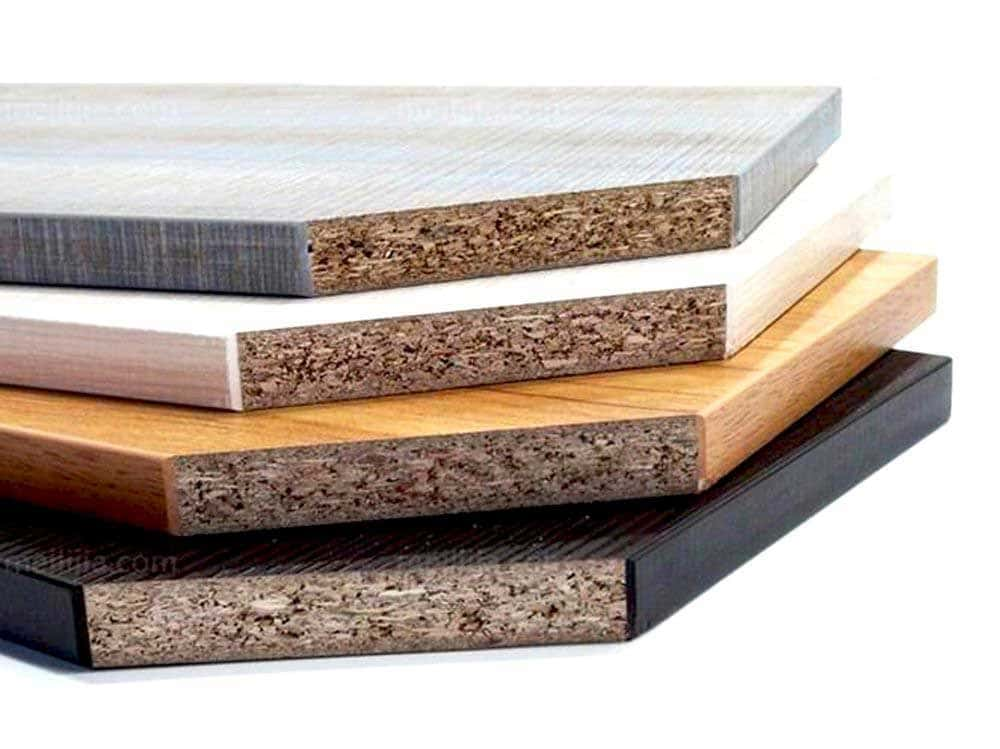

<p>When it comes to selecting materials for your next epoxy project, the choice of MDF (Medium Density Fiberboard) is a popular decision for numerous reasons. Its smooth surface, consistent density, and excellent adhesion with epoxy resin make it an ideal candidate for a variety of crafting and woodworking applications. However, understanding the intricacies of different […]