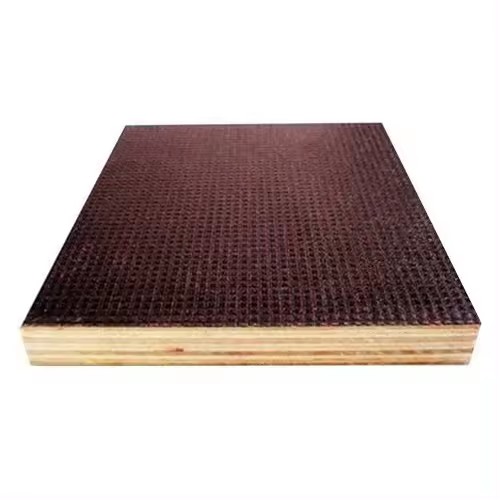

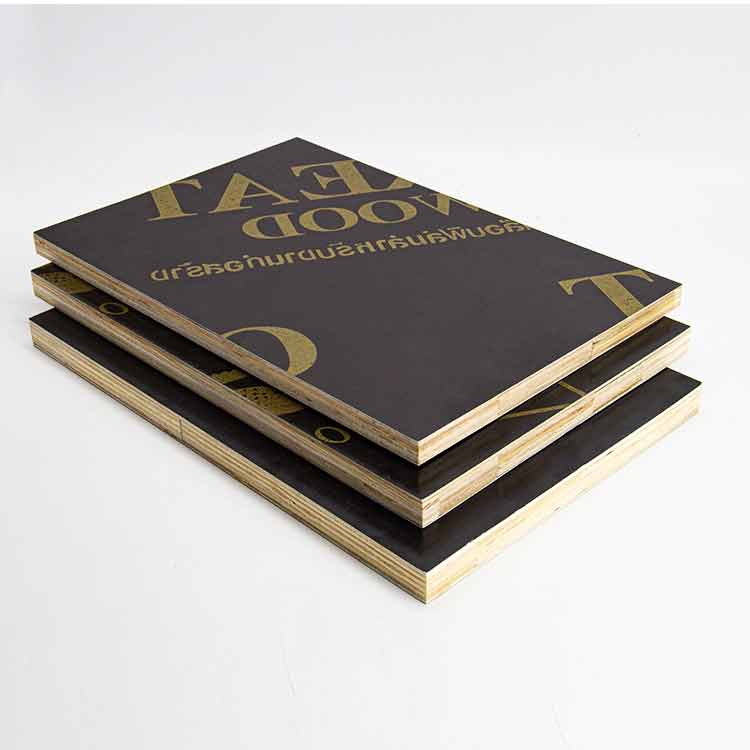

building formwork;

plywood fromwork panels;

board formed concrete veneer;

film faced plywood for concrete forming

The five generations of template evolution have witnessed the development process of building templates, starting with wooden templates and now evolving to aluminum templates, each generation showcasing unique characteristics and advantages. This long and rich history is not only the progress of building template technology, but also a vivid portrayal of the continuous innovation and improvement of the construction industry.

Today, I have summarized the advantages and disadvantages of the fifth generation modeling templates for everyone, hoping to help you understand the development history of modeling templates!

The first generation of wooden templates

Advantages:

Relatively low cost: Wood is a common and inexpensive building material, so the cost of making wooden formwork is relatively low, making it suitable for construction under limited budgets.

Easy to process and customize: Wood has strong plasticity and is easy to process into various shapes and sizes, which can meet the needs of different building structures and provide more customized choices.

Environmental friendliness: Wood is natural, renewable, relatively environmentally friendly, and in line with today’s building philosophy that emphasizes sustainable development.

Disadvantages:

Low durability: Wooden formwork is easily affected by factors such as weather, humidity, and insect damage, and its durability is relatively low, requiring more frequent maintenance and replacement.

Heavy weight: Wooden formwork is relatively heavy, which poses certain difficulties in handling and installation, especially for large-scale construction projects, where labor costs may be higher.

Easy to deform: Wood is prone to expansion or contraction in environments with varying humidity, which can cause deformation of the formwork and affect construction quality.

Second generation steel formwork

The second generation of steel formwork, compared to the first generation of wooden formwork, introduces steel as a sturdy and durable material, bringing a series of new advantages and challenges.

Advantages:

Strong durability: Steel has excellent durability and can withstand greater loads and pressures, making steel formwork more suitable for large-scale construction projects.

High stability: Steel formwork is less susceptible to weather and humidity compared to wooden formwork. Maintaining stability helps ensure the accuracy and consistency of building structures.

Reusable: Due to the strength and durability of steel, steel formwork can be reused, reducing material waste during construction and saving costs.

Disadvantages:

High cost: Compared to wooden templates, the price of steel is higher, which makes the production and use costs of steel templates relatively high, which may increase the overall project cost.

Heavy: The relative density of steel is relatively high, so the weight of steel formwork is relatively large, which may increase the difficulty of handling and installation, requiring more manpower and equipment.

Corrosion and rusting: In humid environments, steel formwork may be affected by corrosion and rusting, affecting its appearance and service life, requiring regular anti-corrosion treatment.

Third generation bamboo templates

The third-generation bamboo formwork, as an innovative material for building formwork, introduces bamboo as a lightweight and environmentally friendly choice, bringing some unique advantages and challenges.plywood formwork 21mm,plywood formwork18mm,

Advantages:

Environmental Protection and Sustainability: Bamboo is a natural and renewable material that grows rapidly and can be replanted and harvested in a short period of time, in line with the concept of sustainable architecture.

Lightweight and convenient: Compared to steel formwork, bamboo formwork is lightweight and easy to handle, which helps simplify the construction process and reduce labor costs.

Sound absorption and thermal insulation performance: The natural texture and structure of bamboo give it good sound absorption and thermal insulation performance, which helps to improve the comfort of buildings.

Disadvantages:

Relatively low strength: Compared to steel formwork, bamboo formwork has lower strength and is not suitable for some engineering projects that require extremely high structural strength.

Limited durability: Bamboo is susceptible to humidity and insect damage, and its durability is relatively limited compared to steel, requiring more meticulous maintenance.

Limited customization: Due to the natural characteristics of bamboo, its customization in shape and size is relatively low, which may not be suitable for some highly customized construction projects.

The fourth generation of plastic templates

The fourth generation of plastic templates is a relatively innovative template material in the construction field, using plastic as the main construction material, which brings some new advantages and challenges.building formwork

Advantages:

Lightweight and high-strength: Plastic materials are relatively lightweight and have high strength, which helps simplify the handling and installation process and reduce construction labor costs.

Strong weather resistance: Plastic templates have good weather resistance and are not easily affected by humidity, climate, and insect pests, maintaining relatively stable performance.

Strong plasticity: Plastic materials are easy to shape into various shapes and sizes, providing more design flexibility and suitable for the needs of various building structures.

Reusable: Plastic templates typically have a longer lifespan and can be reused, reducing material waste and having a positive impact on sustainable construction.

Disadvantages:

Flammability: Some plastic materials may have high flammability, posing certain challenges to building safety and requiring corresponding fire prevention measures.

Relatively high cost: Compared to traditional wood and bamboo templates, the production cost of plastic templates may be higher, which may increase the overall cost of the project.

Environmental impact: Some plastic materials may have a certain impact on the environment, especially during the treatment and disposal process, which may cause some environmental problems.

Fifth generation aluminum template

The fifth generation aluminum template is an advanced template material in the construction field, using aluminum alloy as the main construction material, which has a series of unique advantages and some challenges.

Advantages:

Lightweight and High Strength: Aluminum alloy has the characteristics of lightweight and high strength, making aluminum templates relatively lightweight, easy to transport and install, and possessing high structural strength.

Strong corrosion resistance: Aluminum alloy has good corrosion resistance, is not easily affected by humidity and climate change, maintains relatively stable performance, and helps to extend its service life.

Strong plasticity: Aluminum alloy is easy to process into various shapes and sizes, providing more design freedom and suitable for the needs of different building structures.

Reusable: Aluminum templates typically have a longer lifespan and can be reused multiple times, reducing material waste and promoting sustainable construction.

Good thermal conductivity: Aluminum alloys have good thermal conductivity, which helps to better cope with thermal deformation issues in building structures during use.

Disadvantages:

High cost: Compared to some traditional template materials, the production cost of aluminum templates is relatively high, which may have a certain impact on the overall project cost.

High requirements for processing technology: The processing of aluminum alloys requires advanced production equipment and processes, which may increase the difficulty and cost of manufacturing.building formwork

Thermal conductivity: Aluminum alloys have good thermal conductivity, which may require special consideration in certain situations to avoid adverse effects on building structures.