Plywood supplier is affected:The Rising Whole House Customization Factories in China

Plywood production,Sales of plywood,Plywood supplier,Decoration companies will be affected

What is a whole house customization factory?

- A whole-house custom factory is a factory that specializes in producing custom furniture. Unlike traditional furniture manufacturing plants, a whole-house custom factory designs and manufactures personalized furniture according to the specific needs and spatial characteristics of customers to meet the customized needs of the entire home space.

- In a whole-house custom factory, customers can communicate with designers about their preferences, living habits, and space utilization requirements, and then the factory will carry out custom-made production according to this information to produce furniture that meets the needs of customers, such as wardrobes, cabinets, bookcases, beds, sofas, etc. This customized service can better adapt to the unique needs of different families and provide a more practical solution for real life.

- Whole-house custom factories usually use advanced production technologies and processes to ensure the quality and durability of the products. At the same time, they also pay attention to environmental protection and sustainable development, select environmentally friendly materials, and minimize the impact on the environment in the production process.

- If you are interested in whole-house customization, you can visit the factory in person to learn about their production process and product quality, so that you can better choose the whole-house customization service that suits you. Are you considering decorating your house?

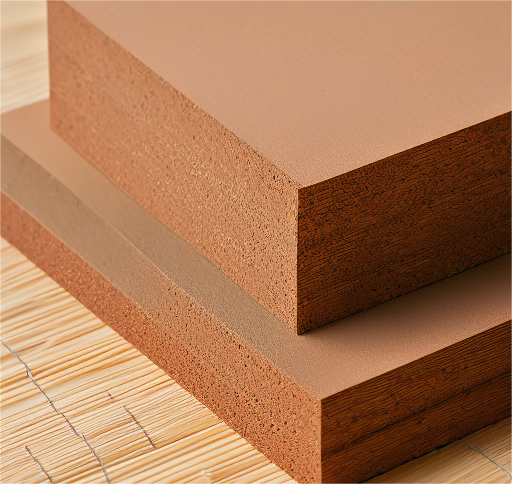

particle board

What are the advantages and disadvantages of whole house customized furniture?

- The advantages of whole house customized furniture are as follows:

– Personalized design: According to the actual needs and space of the house, custom furniture can be designed to better meet the individual needs and usage habits of the user, maximizing the use of space.

– Perfect fit: Customized furniture can be precisely sized to fit the dimensions of the room, making it more harmonious and integrated with the overall decoration style.

– Higher quality: Customized furniture usually uses better materials and production processes, ensuring better quality and durability.

– Tailor-made service: The manufacturer can communicate and cooperate closely with the user, providing professional design and installation services to meet the user’s specific requirements.

– Increased functionality: Customized furniture can be designed according to specific functional needs, such as adding storage spaces or special compartments. - The disadvantages of whole house customized furniture may include:

– Long production cycle: The production cycle of customized furniture may be relatively long,requiring more time for design, production and installation.

– Higher cost: Customized furniture usually costs more than off-the-shelf furniture due to personalized design and production.

– Limited options: Compared to buying ready-made furniture, the options for customized furniture may be more limited, especially in terms of design and style.

– Dependency on manufacturers: Once the furniture is customized, it may be more dependent on the manufacturer for after-sales service and maintenance. - It should be noted that the advantages and disadvantages of whole house customized furniture may vary depending on individual needs and circumstances. Before choosing whole house customized furniture, it is recommended to carefully consider and evaluate your own needs and budget, and communicate fully with the manufacturer to ensure that the final results meet your expectations. Do you have any specific concerns or requirements regarding whole house customized furniture? I can help you further analyze and discuss.

particle board on walls

What type of plywood is commonly used for whole house customization?

- The types of plywood commonly used in whole-house customization may vary depending on the manufacturer and customer requirements, but generally, the following types of plywood are more common:

1. **Solid wood plywood**: Made of multiple layers of solid wood veneers, it has good strength and stability and is suitable for making furniture such as wardrobes and cabinets.

2. **Man-made board plywood**: Such as medium density fiberboard (MDF) or particleboard, these plywood are usually relatively inexpensive, easy to process and finish, and are often used in furniture where strength requirements are not high.

3. **Moisture-proof plywood**: After special treatment, it has good moisture-proof performance and is suitable for furniture in damp environments such as kitchens and bathrooms.

4. **Flame-retardant plywood**: It has certain flame-retardant properties and meets the requirements of fire safety. It is often used in public places or spaces with fire protection needs.

5. **Environmentally friendly plywood**: Using environmentally friendly materials and production processes, it meets environmental protection standards and is friendly to human health and the environment. - When choosing plywood, in addition to considering the type, factors such as quality, environmental performance, thickness, and size should also be considered. In addition, the prices of different plywoods will also vary, and you can choose according to your budget and actual needs.

- If you have further questions about the specific performance or characteristics of the plywood, I can provide you with more detailed information. Are you customizing the whole house for your own home?

plywood company

If you want to know moer about plywood message,pls click blogs pages.